TEMG1

Please contact us at +7‑800‑300‑88‑77

Four-axle shunting gas piston locomotive

STM’s own solution that has no analogues in Russia

Certificate of conformity

1120 HP

Technical specification

Advantages of TGM1

40%

Environment friendly

Cost effective

+

The locomotive runs on LNG, thus reducing CO2 emissions by up to 40% compared to a conventional diesel locomotive.

Specific features

Fuel: liquefied natural gas

Safe gas storage and supply system

State-of-the-art gas leak detection and fire extinguishing systems

Effective solution for shunting operations

Modular design of the locomotive

Single platform solution with diesel locomotives

Load-dependent automatic operation of power sets

Reduction of power consumption due to asynchronous drive

Modularity allows to reduce the duration of overhauls

Optional installation of a video surveillance system and other equipment

Operation by a single driver

Fully complies with modern environmental requirements

Engineering and advanced technology

+40°C

2600 kg

–50°C

- A two-axle bogie ensures that the locomotive fits into curves with a radius of 40 m.

- Wheel pairs with individual drive

Universal platform suitable for a wide range of locomotives

- Total power output of two engines 1120 hp

- Load-dependent automatic operation of power sets

Accumulator batteries don't require maintenance

Microprocessor-based monitoring, control and diagnostic system

- Operation monitoring and equipment control

- Troubleshooting updates

- Recording of all parameters in order to monitor the locomotive’s condition

Improved AKV 5.25 screw compressor unit

- Enhanced reliability

- Built-in troubleshooting capability

LNG reserves allow for up to 5 days of operation without refilling

Cost savings

50% less fuel consumption compared to equivalent diesel locomotives in standard operating modes

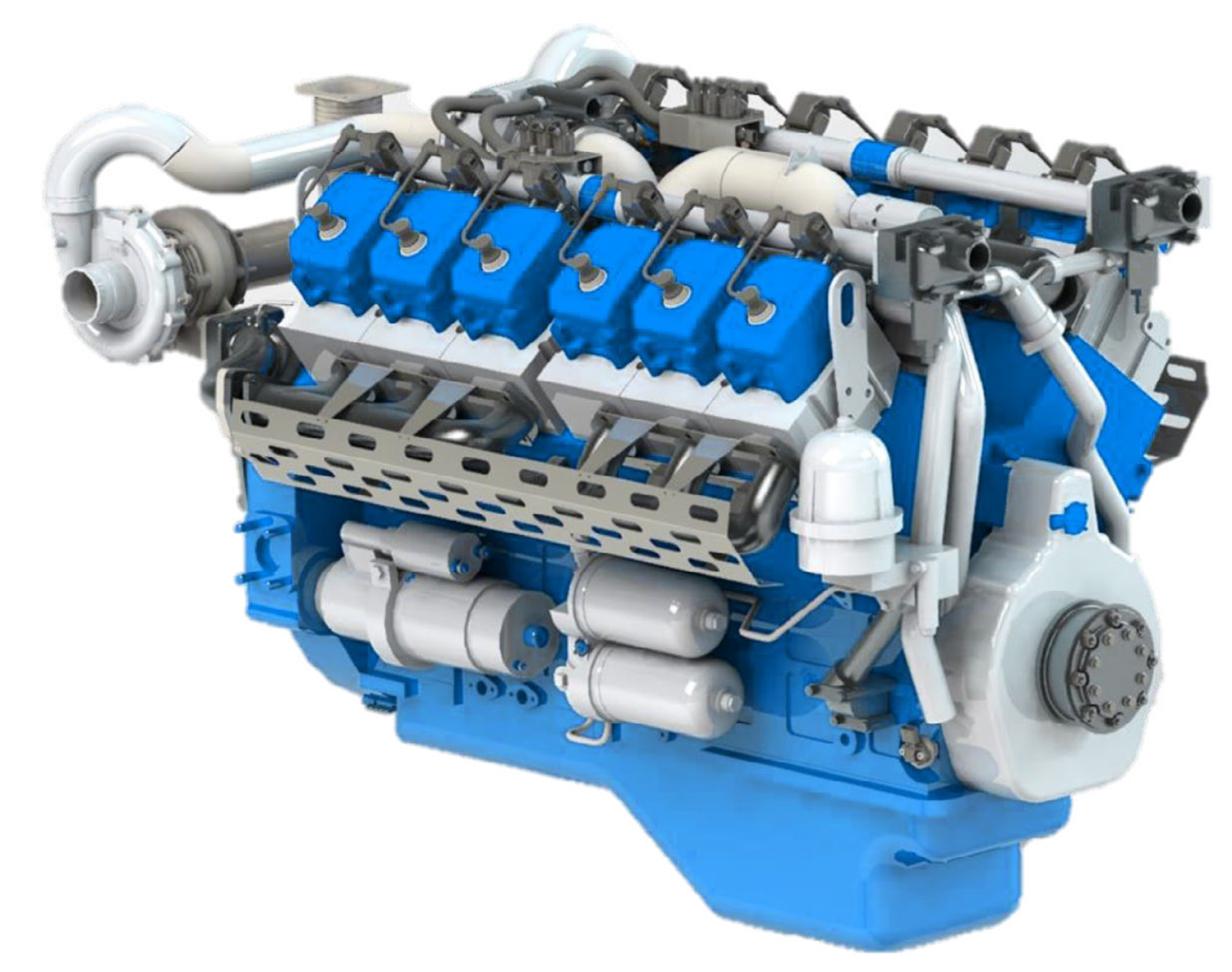

Two gas piston engine power sets

Innovative features and advanced technical solutions

The gas storage and treatment system constitutes a single module and provides storage, gasification of LNG and supply of gas with the required parameters to gas piston engines

Standard filling connection

Storage and gasification module of the gas supply system (LNG)

Safe drainage device

Gas supply pipe set

Locomotive refueling with cryogenic mobile gas tankers

Full refueling time

40–50 min

We would be happy to answer any further questions

STM News